Investor News

Joint Venture Agreement with GrapheneX for Demonstration Project and Capital Raising

Highlights:

- Australia’s largest demonstration of lignite syngas into hydrogen and low-emission electricity

- GrapheneX and ECT to contribute $3.5m each to support the upgrades ($7m in total)

- Phase 2 of COLDry demonstration to commence

- Pyrolysis kiln, 39MW gas turbine and formic acid process to be installed on-site

- Targeting production of syngas, hydrogen, formic acid, agricultural char and electricity

- Targeting net zero emission from hydrogen without Carbon Capture and Storage (CCS)

- Bacchus Marsh site to become fully integrated Waste to Clean Energy/Hydrogen Hub

- ECT has received binding commitments from sophisticated and professional investors to raise $5m via a share placement to fund ECT’s costs in the JVA and provide working capital.

Environmental Clean Technologies Limited (ASX: ECT) (“ECT” or “Company”) is pleased to announce the signing of a binding Joint Venture Agreement (JVA) with GrapheneX. This agreement supports the rollout of Phase 2 of ECT’s Bacchus Marsh COLDry project (the Project) to deliver a world-first demonstration of the Company’s proposed commercial-scale net-zero hydrogen and electricity production. To support the rollout of Phase 2, ECT is also pleased to announce that it has received firm commitments from sophisticated investors to raise $5m under a placement that was joint led by Kaai Capital and Peak Asset Management.

Set to become the largest demonstration of its type in Australia

The JVA upgrades will enable the first-of-a-kind demonstration of low-emission electricity production from syngas and the generation of hydrogen derivative products from lignite and waste biomass blends, making it the largest demonstration of its kind in Australia.

“Based on ECT’s internal engineering modelling, the upgraded Bacchus Marsh plant would have the capacity to produce up to 1000 tpa of Hydrogen that can be used for derivatives like formic acid and dimethyl ether (DME).”

Ashley Moore, Chief Group Engineer, ECT

GrapheneX will commit to supplying a multi-feedstock 39MW turbine to be installed at ECT’s Bacchus Marsh site. GrapheneX will also supply funding of $3.5m for installation of the turbine and the formic acid process equipment. The formic acid plant will demonstrate the production of formic acid (HCOOH) from the syngas product stream. Formic acid is a liquid organic hydrogen carrier that provides a safer, lower-cost hydrogen transport alternative[1] to ammonia or cryogenic hydrogen. In addition, it is also a product in its own right, used as a livestock feed preservative, amongst other applications.

ECT will commit $3.5m to the JVA, from which the company will fund the installation of the pyrolysis kiln and ancillary plant to produce char and syngas from COLDry pellets made from a blend of biomass and lignite.

ECT Managing Director, Glenn Fozard commented:

“Once installed, the process will be the largest hydrogen production capability from lignite. Add to that the largest demonstration of low emission electricity from lignite syngas, and we have a site of national significance. ECT shareholders and GrapheneX should be proud of this proposed development and the facility’s national profile will support increased interest from both industry and Government.”

The Project, similar to the HESC[2] project, aims to be a fully integrated supply chain solution for hydrogen. However, the key difference for ECT’s project is that, instead of focusing on high-purity hydrogen, it will focus on hydrogen derivatives, which solve the immediate storage and transportation challenges. In addition, the Project does not require the CCS infrastructure that is being planned to curtail emissions for Blue Hydrogen projects. By eliminating two of the biggest challenges facing the immediate deployment of hydrogen production plants, the Project allows ECT and GrapheneX to focus on technical scale-up, commercial optimisations and further emissions and waste improvements.

Phase 2 of COLDry Demonstration Project to Commence

Phase 2 of the Project was placed on hold in October 2021 as part of the Company’s strategic review to allow a re-focus on formalising relationships with potential project partners, with the view to accelerate commercialisation and diversify project risk and funding.

The rollout of Phase 2 will establish R&D capability to support the development of:

- Hydrogen use in transport & electricity markets

- Fertility improvements to agricultural char

- Utilisation of char as a fertiliser & soil health feedstock

- Assessment of higher value carbon applications:

- Graphitic carbon

- Battery anodic carbon

- Graphene

The Company’s recently released corporate presentation highlighted the revised Phase 2 development plan, outlining the objective of demonstrating a net zero-emission hydrogen and agricultural char process, including:

- Char and syngas production

- Formic acid production

- Dimethyl ether production

- Hydrogen production

- Electricity production (hydrogen fuel cells & gas turbine)

Phase 1 of the Project, focusing on the scale-up of the Company’s world-first zero-emission COLDry lignite drying process, commenced commissioning in March.

Paving the way for ECT’s headline Net Zero Emission Hydrogen (NZEH2) Refinery project in Latrobe Valley

The commitment to Phase 2 of the Bacchus Marsh COLDry project also marks the next major step for the Company’s previously announced headline NZEH2 Refinery Hub project planned for deployment adjacent to the Yallourn mine and power station complex in Victoria’s Latrobe Valley.

Managing Director, Glenn Fozard commented:

“We are excited to continue developing our demonstration project at Bacchus Marsh in joint venture with GrapheneX. The addition of a turbine on-site, along with funding to build the pyrolysis kiln and formic acid process, will elevate the profile of our Hydrogen Hub at Bacchus Marsh and provide a working demonstration of technology that is proven, ready for deployment and most importantly, demonstrably net zero emission.”

Chairman of GrapheneX, Stephen Wee, commented:

“By providing the use of the turbine at the Bacchus Marsh site, GrapheneX is pleased to support the establishment of Australia’s largest demonstration of low-emission syngas as a feedstock for electricity. We see this as clear evidence that the partnership of ECT and GrapheneX is leading the charge towards implementing Victoria’s net-zero hydrogen refinery project in the Latrobe Valley.”

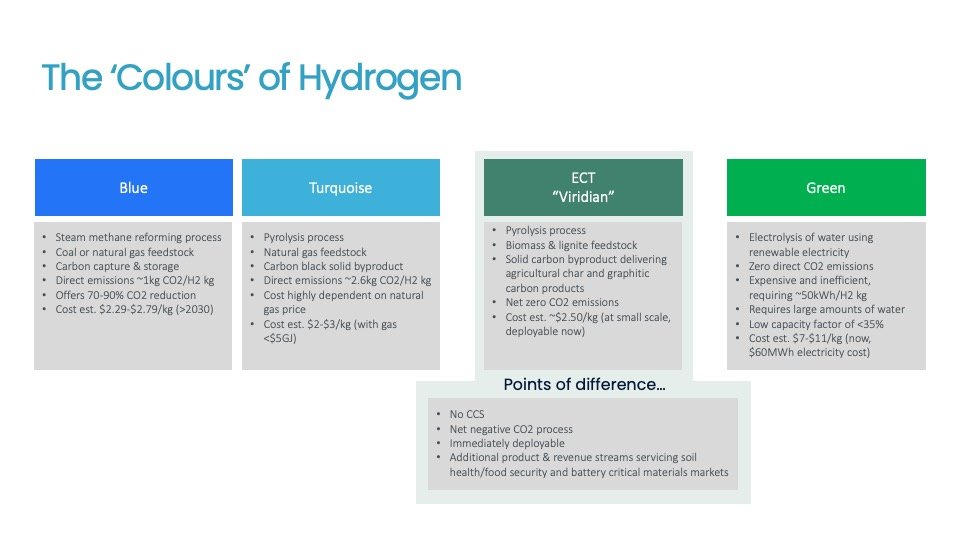

Introducing “Viridian Hydrogen”

With a rapidly emerging hydrogen space and a range of production methods competing for market share, colour codes have been loosely adopted to identify the production source and, by extension, the emissions profile.

The process being developed by ECT and GrapheneX is in a colour category of its own due primarily to its net-zero emission profile without the need for CCS (see table below).

The critical point of difference is the effective transformation of lignite, combined with waste biomass, into a valuable multiproduct stream:

- Clean energy – hydrogen and low emission electricity

- Soil health – agricultural char

- Critical minerals – graphitic carbon, battery anodic carbon & graphene

This outcome is achieved with net-zero emissions and zero waste discharge, delivering a transformative solution that allows for billions of dollars of improved economic value to be derived from Victoria’s lignite resource, aligned to emerging clean and circular industries and environmental sustainability.

Bacchus Marsh site to be developed into integrated Waste-to-Clean Energy Hub

ECT has commenced planning for the long-term use of its Bacchus Marsh site to become a fully integrated waste-to-clean energy hub.

The aim is to collaborate with both current and new partners to showcase a commercial application of many different low emission processes for turning waste into valuable energy products with a low to net-zero emission profile.

This will see further collaboration with industry partners over the coming weeks and months to identify leading-edge technology, recycling and refinery solutions for:

- Rare earth elements (REE)

- Graphene and graphitic carbon conversion

- End of life tyres

- Waste plastics

- Biosolids and other high costs waste biomass

- Hydrogen and low emission electricity end-use

All technologies will be selected for their impact targeting:

- Synergies with ECT’s existing technologies and processes at Bacchus Marsh

- The circular economy

- Low emissions or Net Zero Emissions capability

- Cost-effective production of high-value products like REE

ECT is currently in discussions with multiple parties, some advanced and some emerging, for technology acquisitions, collaborative integration of plant and equipment and strategic joint ventures in support of this initiative.

Joint Venture Key Terms

- Completion of the COLDry plant to produce feedstock for the pyrolysis kiln

ECT is responsible for the completion of the COLDry plant:

- Installation of the pyrolysis kiln to produce char and syngas

- ECT will be responsible for installing the pyrolysis kiln and associated equipment to deliver syngas to downstream applications.

- ECT is responsible for the estimated budget of $3.5m

- Installation of the open cycle gas turbine to produce electricity using the syngas supplied by ECT

GrapheneX will be responsible for:

- installing the open cycle turbine at the Bacchus Marsh Site

- syngas receiving and distribution infrastructure

- electrical infrastructure required for the turbine and connection through to the grid

ECT is responsible for:

- providing a suitable location for the installation of the open cycle gas turbine.

- the supply of syngas to GrapheneX offtake point.

- Upgrade of the formic acid (FA) process using syngas

GrapheneX will be responsible for:

- Developing and installing the FA micro-pilot plant, supplied by bottled gas streams during initial process calibration trials

- Scale-up of the micro-pilot plant to accept production syngas streams from ECT’s demonstration plant

- the estimated budget of $3.5m.

ECT is responsible for:

- providing a suitable location to accommodate the FA plant(s)

- the supply of syngas to the GrapheneX offtake point

ECT will have no claim over any IP generated from the FA process or turbine demonstration and GrapheneX will have no claim over any IP generated from the COLDry-pyrolysis kiln demonstration or the char and syngas generation.

About GrapheneX

GrapheneX is an Australian pioneer in developing innovative manufacturing processes and material technologies capable of powering the fourth industrial revolution. The company is focused on developing technically feasible and commercially viable manufacturing processes for smart materials and digital platforms to enable Industry 4.0. GrapheneX Pty Ltd is also a founding industry partner of the Clayton Hydrogen cluster and plays a key role to test, trial and demonstrate new and emerging hydrogen technologies.

Placement Details

The Company is pleased to advise that it has received firm commitments to raise gross proceeds of $5m via a share placement to institutional and sophisticated investors. The share placement was strongly supported and will see several new institutional shareholders join the Company’s register.

The share placement will comprise the issue of 166,666,667 new fully paid ordinary shares (“Placement Shares”) at an issue price of $0.03 per share (“Placement”). Completion of the Placement is expected to occur on or around 3 May 2022. In addition to the Placement, for every 3 shares issued under the Placement, the Company will issue 2 free attaching listed options with the same terms as the Company’s existing listed option on issue (each exercisable at $0.03 expiring 23 February 2023 with ASX code ECTOE (‘’Placement Options’’). The first attaching Placement Option will be issued pursuant to the Company’s 15% capacity under Listing Rule 7.1 and at the same time as the Placement Shares. The second Placement Option is subject to shareholder approval to be sought at a general meeting of the Company proposed to be held in June 2022 (Meeting).

166,666,667 of the Placement Shares shall be issued pursuant to the Company’s 15% capacity under Listing Rule 7.1.

The issue price represents a 9% discount to the last traded share price of 0.033 cents, 9% discount to the 5-day volume-weighted average share price, and 10% discount to the 30-day volume-weighted average share price.

Kaai Capital Pty Limited (‘’Kaai’’) and Peak Asset Management (‘’Peak’’) have been separately appointed to act as Joint Lead Manager for the Placement (JLM's). In consideration for lead managing the Placement, the Company will pay the JLMs a fee of 6% of the amount raised and issue to them (or their nominees) a total of 10.2M ECTOE options. Funds raised under the Share Placement will be applied as follows:

- $3.5m to fund ECT’s obligations under the JVA, being the installation of the pyrolysis kiln and site preparation for the turbine, formic acid process and Hydrogen Hub;

- $1.2m for general working capital; and

- $0.30m in capital raising costs.

This announcement is authorised for release to the ASX by the Board of ECT.

For further information, please contact:

INVESTORS

Glenn Fozard

Managing Director [email protected] / +613 9849 6203

MEDIA

Adam Giles

Marketing & Communications Manager [email protected] / +613 9849 6203

[1] Formic acid is liquid at ambient temperature and pressure, unlike other proposed methods which require low / extremely low temperature and high pressure, and specialised transport vessels.

[2] HESC refers to the Hydrogen Energy Supply Chain pilot project which aims to safely demonstrate the production and transport of clean liquid hydrogen from Victoria’s Latrobe Valley to Japan.