Investor News

Why should investors care about hydrogen?

You've probably read it somewhere... 'hydrogen is the fuel of the future'.

It appears hydrogen could play an increasingly important part in our future energy mix, especially in transport. But it will take time, effort and investment to realise its potential.

The article below from The Flinders News tells us that the world's biggest wind—and solar-powered hydrogen production plant is slated for development in South Australia.

Before we take a look at what that means, let's take a step back and ask, why hydrogen and why is ECT interested?

Firstly some background.

Why is hydrogen seen as an attractive fuel?

- There are no CO2 emissions

- It's seen as a path to decoupling light transport from oil-based fuels

- The range of a hydrogen fuel cell vehicle (HFCV) is better than battery-powered electric vehicles, and the refuelling time (assuming you have the infrastructure) is only 5-10 minutes, compared to 75 minutes to fully charge a Tesla

- Pound for pound, hydrogen packs three times the energy of natural gas

Hydrogen production can be achieved by one of two primary paths:

- Fossil fuel splitting via steam-methane reforming (CH4 + H2O = CO + 3H2)

- Water splitting via electrolysis (149MJ energy in, 141.8MJ out)

It's a challenge to make hydrogen. Both paths have their pros and cons.

The standard industrial method of producing hydrogen uses fossil fuels, typically natural gas. When you heat up coal or natural gas, you get hydrogen–but you also get CO2 emissions. Coupled with carbon capture and storage technology, this is the route being explored by the Japanese in Victoria's Latrobe Valley.

Alternatively, hydrogen can be made from water by splitting water molecules via a process called electrolysis. Unlike steam reforming of natural gas, electrolysis has zero CO2 emissions. The drawback is that it also takes a lot of energy—more energy than what is actually contained in the resulting hydrogen. Catalysts like platinum can speed up the reaction and help save energy, but they are also expensive. New research has identified nickel as a relatively cheap catalyst, but it is still not cheap enough.

Our own research uses a catalyst to produce hydrogen from brown coal.

Then there's the issue of storage and distribution. Regardless of which production path you take, storage and distribution is an industry-wide challenge.

Hydrogen is difficult to contain. At room temperature and pressure, hydrogen's density is so low that it contains less than one-three-hundredth the energy of an equivalent volume of petrol. In order to fit into a reasonably sized storage tank, hydrogen is liquefied or compressed into a denser form. This takes energy, adding cost.

Distribution is also a challenge. Most hydrogen is transported either in liquid form by tankers or as compressed gas in cylinders by trailers. Both methods are inefficient. Trucking compressed hydrogen 100 km, for instance, burns diesel equivalent to 7% per cent of the energy the hydrogen stores. It also requires a lot of round trips: A truck that can carry enough petrol to refuel 800 cars could only carry enough hydrogen to fuel 80 vehicles. Pipelines are cheaper and more efficient than trucking hydrogen, but because they require special treatment to avoid hydrogen embrittlement of the metal, they cost a lot upfront.

This brings us back to the article below. The renewables industry sees hydrogen as a potential energy storage solution through water splitting.

But what about the high energy cost of splitting water? That doesn't change. What does change, in principle, is how and where the energy comes from.

We know that wind and solar power are intermittent.

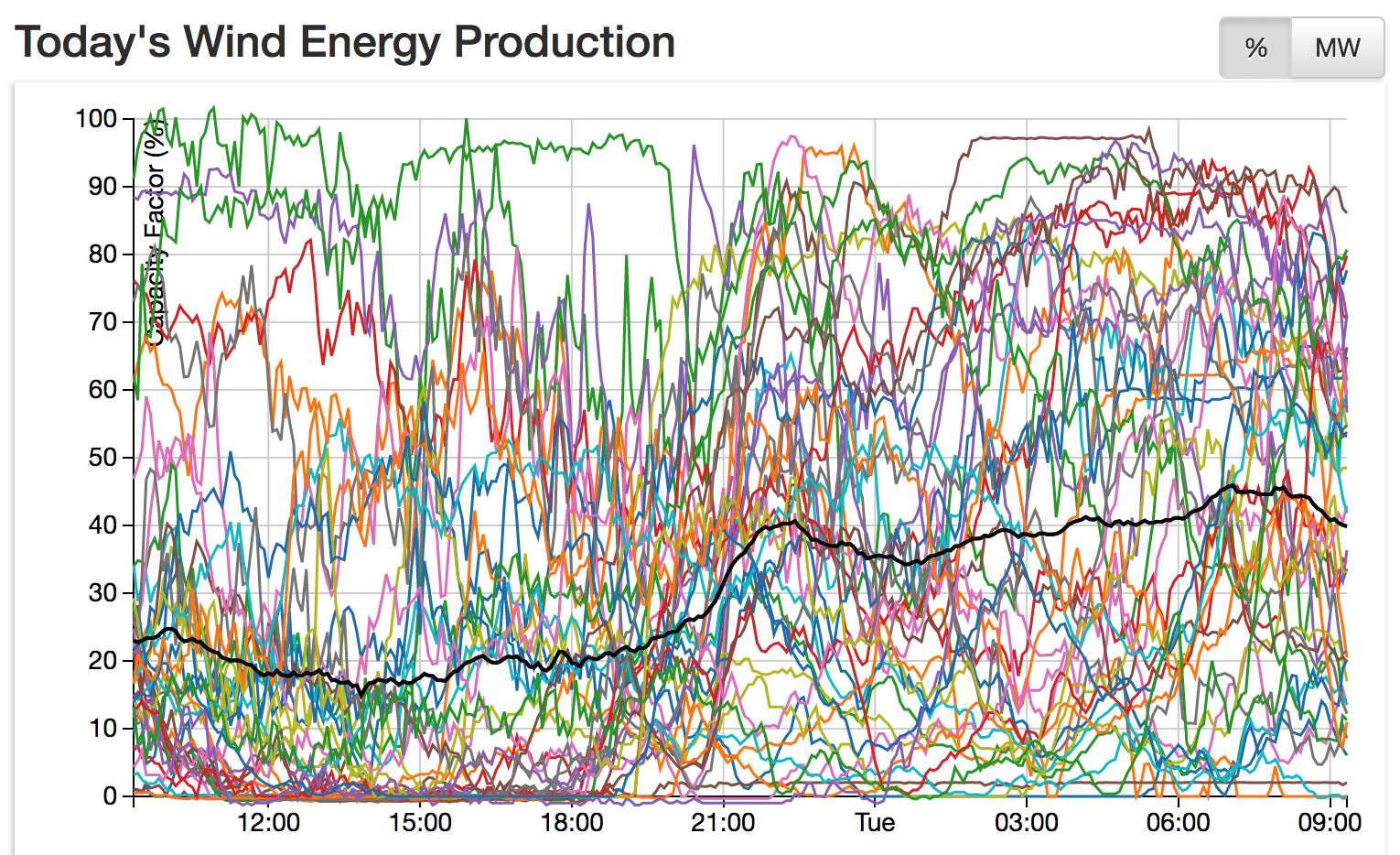

Wind can vary significantly, like this:

Now, take a closer look at that chart. The highest output for wind power was between 21:00 (9 pm) and 09:00 (9 am). The electricity demand is low overnight, so any unused electricity would simply go to waste. Under conditions where wind power generation exceeds the momentary demand, it makes sense to channel this unused electricity to hydrogen production. This essentially stores that unused wind energy as hydrogen, to be released later, either in-situ via fuel cells back into the grid or exported for use by HFCVs.

The article provides a few numbers:

- $600 million investment

- 150MW solar (10% efficiency factor = 15MW)

- 250MW wind (30% capacity factor = 75MW)

- 20,000 kg hydrogen per day (7,300 tonnes per year)

For context, the USA consumes 10 million tonnes a year.

But hydrogen does pack a punch. That 7,300 tonnes of hydrogen is enough to power 32,000 cars annually. Not a bad start.

What about the cost? Sadly, reliable figures are hard to come by.

The article tells us the investment is $600 million. Assuming that's an all-in project cost with a project life of 25 years, we get a base cost per kilogram of $3.29. That's without distribution or storage costs. A 'gate price' that's roughly equivalent to 6 cents per kilometre (8kg per 480km) when used in a hydrogen fuel cell vehicle.

Petrol costs around 10c per kilometre (A$1.30/L & 8L/100km), including refining, distribution, taxes, and retail margin.

Petrol prices in Australia consist of about 42% refinery cost, 42% taxes, and 16% wholesale and retail costs. So, the 10c per kilometre cost of petrol has a base of 4.2 cents per kilometre, 30% less than the base cost of hydrogen from the project.

This is by no means an exhaustive analysis, but it does give us an indication of where things stand and a glimpse at where the hydrogen industry needs to head to compete with petrol.

One clear thing, the political will is building momentum around hydrogen. Japan is investing considerably, with its eye on Victoria's brown coal, encouraged by the Victorian state government's eagerness to find a greener application for its world-class resource.

With that in mind, let's turn to our interest in hydrogen.

We've previously announced research into our hydrogen production process called COHgen; Catalytic Organic Hydrogen generation.

You'll understand that we're not at liberty to disclose the details regarding our COHgen process due to the need to secure the intellectual property via the patent process first.

Suffice it to say that the invention of our HydroMOR process as an improvement over the Matmor process took our researchers in new and interesting directions, resulting in new discoveries and a series of inventive steps that led to COHgen.

Experimental data suggest the COHgen process may be more efficient than the current dominant hydrogen production method, which involves the ‘steam reforming’ of natural gas.

If successfully commercialised, COHgen has the potential to generate hydrogen from brown coal, delivering a higher-value product from a low-cost resource for a market that is expected to grow exponentially in the coming decades with the emergence of hydrogen fuel cell vehicles (HFCVs).

The interest in and funding of renewable hydrogen research and projects by the SA government indicates a broader global interest in hydrogen. It's difficult to assess the economics of hydrogen from renewables at present, and it's too early for us to make any solid estimates of the potential future cost of a large-scale COHgen plant.

Our aim is to advance COHgen through the current lab-scale development phase in order to begin concept development and indicative costing of potential plant designs to understand the techno-economic profile compared to both natural gas and renewable hydrogen production methods.

Ultimately, the economics will decide which production path dominates, but we suspect there may be room for both.

Read more...

World’s largest solar and wind-powered hydrogen plant to be built at Crystal Brook

7 March 2018 | The Flinders News | Piper Denholm

The World’s largest solar and wind-powered hydrogen plant is expected to built in the Mid North’s Crystal Brook.

The State Government has awarded Neoen, the same company who delivered the Tesla battery in Jamestown last year, $1 million from their Renewable Technology Fund, to be put towards a 50MW electrolyser facility on wind and solar farm.

The project follows the release of the Hydrogen Roadmap for South Australia in September last year, which was designed to accelerate investment in hydrogen technologies throughout the state.

Source: World’s largest solar and wind powered hydrogen plant to be built at Crystal Brook