Investor News

Shareholder Update - April 2016

Wednesday, 20 April 2016: Environmental Clean Technologies Limited (ASX: ESI) (ECT or Company) is pleased to provide the following general update to shareholders.

Topics

- India activity update

- ECT appoints new Matmor Project Manager

- NLC shareholders pass amendments to accommodate new business activities such as Matmor

- Bacchus Marsh high volume test facility update

Topic 1: India Activity

Further to our announcements on 8 and 19 February and 14 and 23 March 2016 updating the market on activities in India, the Company is pleased to provide a progress update on the Coldry-Matmor project in Neyveli, India.

The Company has continued to advance the Techno-Economic Feasibility (TEF) study with leading pyro-metallurgical engineering firm M.N. Dastur and confirms the study remains on track for completion during June 2016.

The TEF study is deliverable under the Tripartite Collaboration Agreement announced on 27 January 2016. The intent of the TEF study is to provide an appropriate level of data required to support the investment decision-making process within NLC and NMDC.

The TEF study includes a comparison of conventional primary iron making process routes involving the review of capital, raw material and operating costs on a finished tonne of steel basis. Key metrics including Net Present Value (NPV) and Internal Rate of Return (IRR) will be highlighted for comparison to reinforce the business case for investment at R&D scale on the way through to commercial scale.

As previously announced, the Coldry process design developed with Thermax in India is well advanced and has already established sufficiently robust capex and opex estimates.

Current activities include:

- Mass & Energy Balance (MEB): Progressive development and refinement of the MEB calculations. This work informs the process parameters based on current knowledge and covers material flow through the process, kinetic modelling, energy requirements for the plant operation, and thermo-chemical reduction mechanisms. The aim is to support appropriate estimation through to commercial scale which will then be the subject of pilot scale evaluation programs.

- Process Parameters: the MEB and process calculations inform the specifications for the physical aspects of the plant design including retort dimensions and structural, piping, electrical and mechanical facets to arrive at appropriate capital estimates that will be subsequently tested and refined through pilot development.

- Technology Comparison: Parameters for a competitive iron making technology comparison have been defined based on recommendations from M.N. Dastur. The reasonable capacity for comparison has been identified, as have the alternative technologies to be evaluated for comparison with Matmor. M.N. Dastur is leading this comparative process, using their vast experience in iron, steel and metals engineering and production.

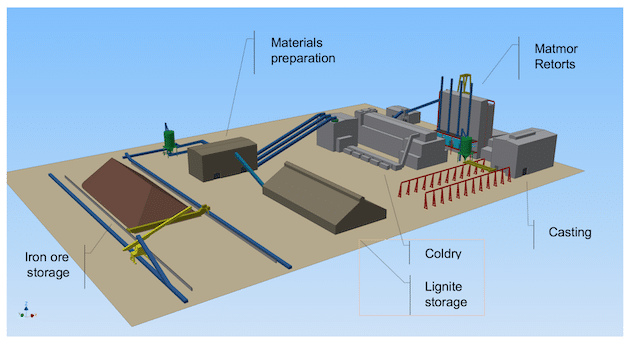

- Indicative Layout: Refinement of an indicative commercial scale Matmor plant layout is progressing (pictured below).

Land usage is a priority consideration when planning such projects in India. The layout provides a basis for understanding the land area required to be set aside, catering for initial pilot activity and allowing flexibility for a multi-staged expansion to demonstration scale and beyond, as deemed appropriate. As an indicator, the integrated Coldry and Matmor footprint is projected to be around 50% less than an equivalent blast furnace facility.

Further, assuming success at pilot scale, the parties envisage scale-up of the process to commercial demonstration capacity ahead of broader rollout. The diagram below shows a Matmor facility of 500,000 tonnes per annum capacity, with layout considerations providing for further expansion to 1,000,000 tpa.

TEF Study Background

On 19 February the Company provided a general update, flagging the convening of the Indian project working group, which set in motion the work plan to deliver the TEF study for the integrated Coldry-Matmor R&D project in India.

The project working group is led by ECT and consists of representatives from NLC and NMDC and is supported by Thermax (Coldry EPC engineers) and M.N. Dastur (Matmor design engineers).

The objective of the working group is to deliver the TEF study, which is an integral requirement of the project development process in terms of appropriately documenting the business case for the prospective investment of funds for the pre-commercial, integrated Coldry Demonstration and Matmor Pilot plant.

TEF Study Next Steps

The TEF study working group will convene in Chennai, India next week for its third workshop focused on advancing aspects of the Matmor engineering, including development and review of capital figures.

Topic 2: Matmor Project Manager Appointed

The Company is pleased to announce the appointment of Mr Lachlan Bartsch to the position of Matmor Project Manager.

Mr Bartsch is a Metallurgist and Project Manager with considerable process and plant development and operating experience both in Australia and overseas, with over 6 years’ experience in tier 1 engineering firms.

ECT Managing Director, Mr Ashley Moore welcomed the appointment, stating “Mr Bartsch will join our Company at a crucial stage in the advancement of our Matmor technology to pilot scale and beyond. With experience in extractive metallurgy and minerals processing across a range of sectors including gold and nickel and a track record in the project management and development of minerals processing plant, Mr Bartsch's skill set will complement the existing team and support the increased project management activity as we work through and conclude the TEF study and drive the project in India.” He will commence service later in May.

Topic 3: NLC shareholders pass amendments to accommodate new business activities such as Matmor

Consistent with the previously stated intent of the parties to develop Coldry and Matmor, NLC has recently ratified several administrative changes to position itself to expand its business activities.

These administrative changes include:

- The change of name from “Neyveli Lignite Corporation Limited” to “NLC India Limited” in recognition that it is diversifying its business activities and expanding its operations beyond mining and power generation in the local Neyveli area.

- Integration, both forward and backward along the energy value chain and diversification beyond mining and coal-fired power generation into various mineral extraction and upgrading activities, including the production of iron using lignite instead of coking coal, and dried lignite fuels, and processed derivatives.

ECT Managing Director Ashley Moore commented, “We understand there has been a level of interest by shareholders in these recent administrative changes. While we understand where this interest stems from it’s important to know that these changes by NLC are procedural in nature, and are part of the broader change in their business focus. Some aspects relate directly to ECT, and this is entirely consistent with our tripartite agreement which laid out the foundation for our longer term relationship.”

Topic 4: Bacchus Marsh High Volume Test Facility

The Company has previously detailed (19 Feb 2016 & 14 Mar 2016) the current upgrade program for the Coldry Pilot Plant near Melbourne aimed at enhancing volume and R&D capability.

The requirement for higher testing capacity has been driven by the identification of the need to provide a robust R&D facility that can provide sufficient flexibility and volume of Coldry product to satisfy minimum quantities for end user testing in large test boilers and live generation systems.

Further, the upgrades will be targeted at increasing efficiency and accuracy in the testing of new brown coals with the aim of reducing test program cycle times in the pursuit of new knowledge and intellectual property.

The Company is pleased to report that most aspects of the upgrade scoping study have been completed, with key outcomes and implementation timeframes expected to be advised during May.

In preparation for the capacity upgrades, the Company has identified process safety and reliability improvement opportunities across several supporting plant elements. This preparatory work has commenced in parallel to the conclusion of the scoping study.

For further information, contact:

Ashley Moore – Managing Director [email protected]