Technology

The world’s most efficient drying process for high moisture content feedstocks.

- Low temperature

- Low pressure

- Reduces +50% moisture to <15%

- ~200% increase in calorific value

- Zero emissions

- Option to harvest evaporated water

- Thermally stable pellet = storable & transportable

- Feedstock for higher-value applications including iron & steel, hydrogen, fertiliser and other fuels

“One distinct advantage of COLDry is the relative low heat requirements in the drying process, allowing for the opportunity to make use of waste heat from an industrial facility or power plant.”

Dr Victor Der - Former Assistant Secretary for Fossil Energy, US Dept. of Energy & General Manager, North America, Global CCS Institute

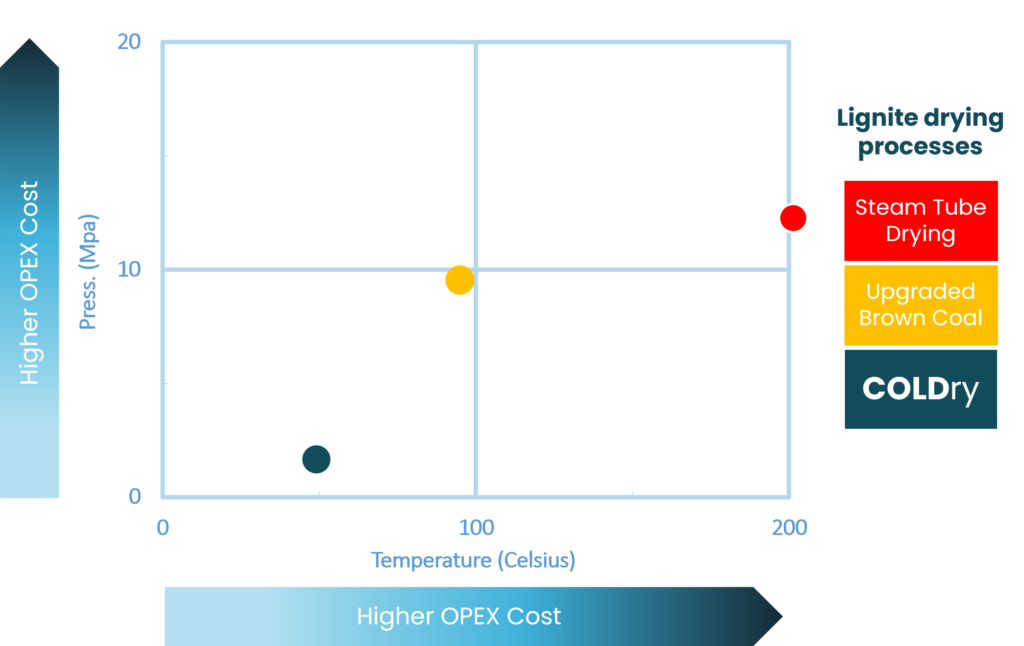

- High pressure and high temperature = high energy cost

- Steam tube drying is the conventional lignite drying method over the past century

- UBC is a recently developed high temperature, high pressure method

- COLDry is the world’s first low temperature (35-45°C), low pressure drying method capable of producing a higher value product via a low cost, zero CO2 process