Technology

Detail

The world’s most efficient drying process for high moisture content feedstocks.

Environmental Clean Technologies Limited is developing a unique, zero-emission, low-cost method to dry lignite and transform this abundant, but widely unusable resource into a resource for the production of clean hydrogen, agricultural char, industrial chemicals and critical minerals.

Based on research initially conducted by CRA and the University of Melbourne in the early 1980s, the technology – COLDry – is a patented process that changes the naturally porous form of lignite to produce a dry, dense pellet, via a process called ‘densification’.

The COLDry process offers benefits, including:

- A process that has been tested and proven successful on a wide range of lignite types

- A more energy-efficient process for drying lignite than conventional methods

- Zero direct CO2 emissions, enabling low and zero-emission downstream applications

When applied to high-moisture content lignite and some sub-bituminous coals, the mechanically simple COLDry process produces a feedstock in the form of densified pellets that are stable, easily stored, can be transported and contain a high energy value, whilst significantly reducing CO2 emissions compared to its original form.

The Lignite Challenge

- Low net energy values restrict available avenues to create value from lignite assets

- High moisture drives high CO2 intensity, limiting its use

- Its can spontaneously combust, restricting its use predominantly to mine-mouth applications

Balancing these disadvantages are the positive traits of lignite:

- High levels of high-value material

- Typically low ash and sulphur levels

- High chemical reactivity, which is desirable in higher-value conversion processes, including hydrogen, char and their derivatives

What will Drive Coldry Adoption?

Economic Security

- Re-valuation of lignite reserves based on the pivot away from emissions-intensive power generation to low and zero-emission applications

- Hydrogen market development and the shift away from hydrocarbon use for transport

- Opportunity to diversify into new product streams – Coal-to-liquids (CTL), fertiliser (Urea) etc

- Value-added industry and jobs, enabled by a cost-effective drying solution

Energy Security

- The growing global demand for high-quality energy sources and the supply-demand imbalance means that escalation of energy pricing is our future reality

- Ambitious hydrogen market development goals globally

- The exit of legacy coal power generation assets and the resulting high cost of electricity network storage and support infrastructure required to underpin reliability of increased wind and solar deployment

Climate Security

- Current focus on climate change has resulted in significant implications for lignite use due to the high level of CO2 emissions from historic power generation

- Provides a least-cost abatement solution for markets with a carbon price

- COLDry enables the deployment of affordable, reliable low and zero-emissions solutions for a range of hard-to-abate problems, such as iron and steel making, clean hydrogen production and agricultural char production

Features & Benefits

The COLDry Process offers some unique features, with the end product, in turn, having some unique attributes. In summary, these are:

The Process

- Uses low-grade waste heat, lowering energy costs and reducing the CO2 footprint

- Is simple & mechanical, providing high reliability and easier maintenance

- Is low temperature and low pressure, reducing energy consumption and extending equipment life

- Is modular, immediately deployable, and consists of prefabricated components for easier construction in remote installations

- Provides enhanced power station efficiencies through reduced evaporation losses Provides ‘Class A’ quality water as a by-product

The Product

- Exponentially enhanced net energy content increased up to 285% for 60% moisture Victorian Latrobe Valley Lignite

- The self-ignition tendency of typical lignite is greatly reduced to that of average black coal

- Gateway feedstock for higher-value applications

Unique

- ECT’s Coldry technology is a scalable, cost-effective lignite drying solution that produces a storable, transportable, energy-rich solid fuel pellet ideal for the applications such as coal to liquids, gas and fertiliser.

The COLDry Pilot Plant has informed the design of the commercial-scale Coldry modules that will underpin commercial plants.

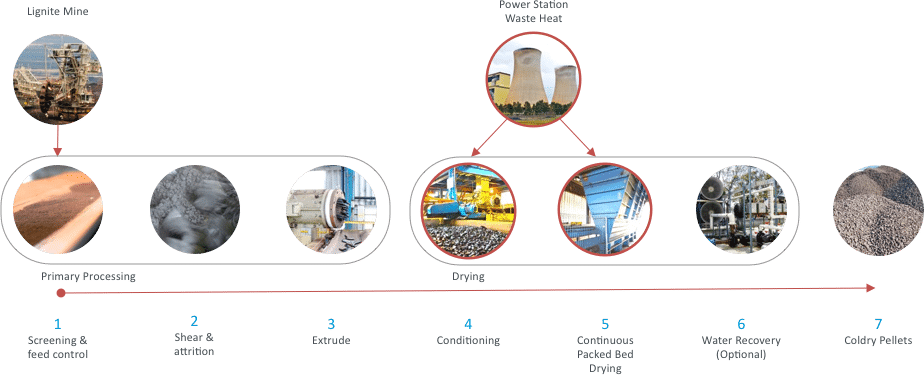

Process Diagram

COLDry is a patented process that changes the naturally porous form of lignite to produce a dry, dense pellet, via a process known as ‘densification’.

The following process is applied:

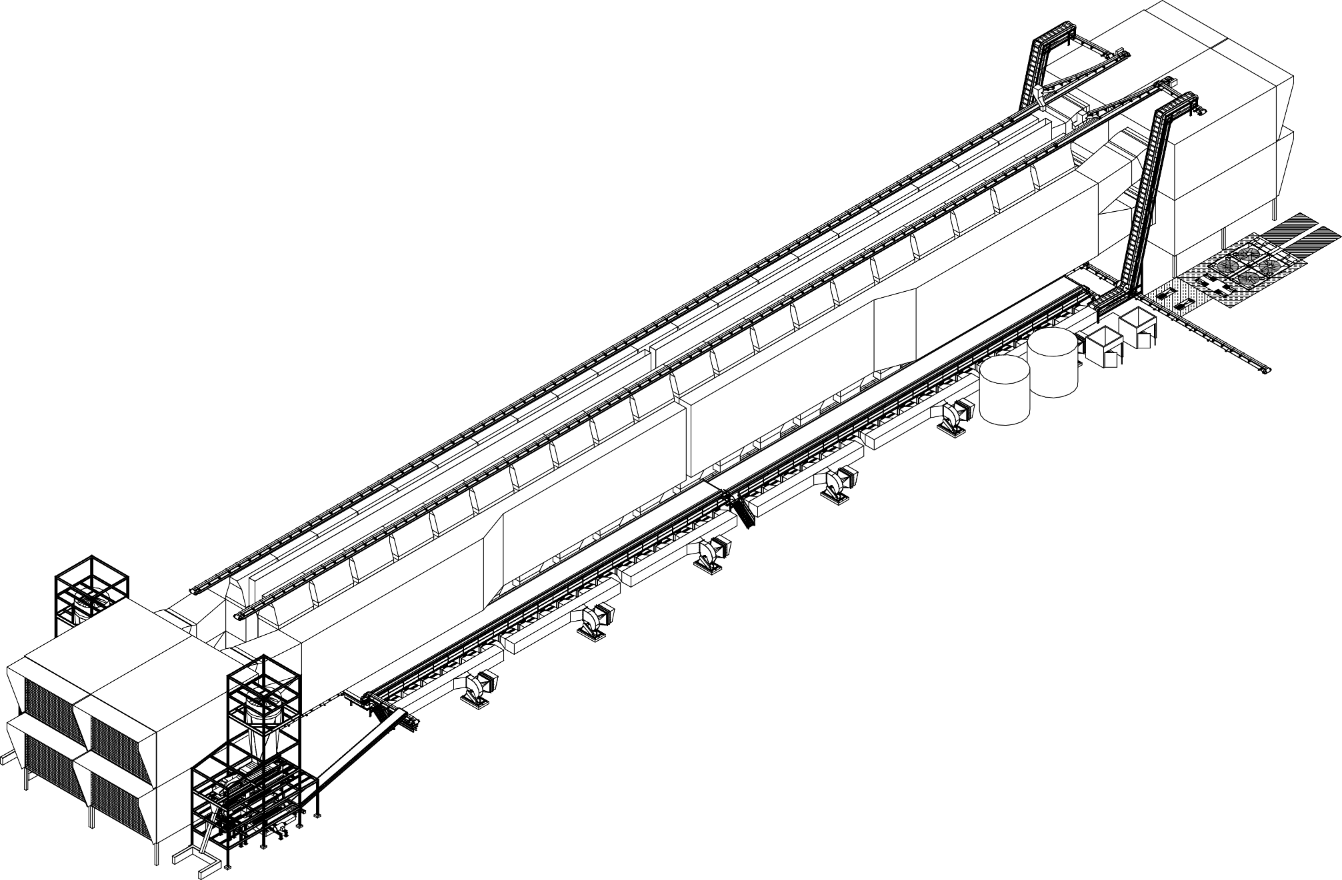

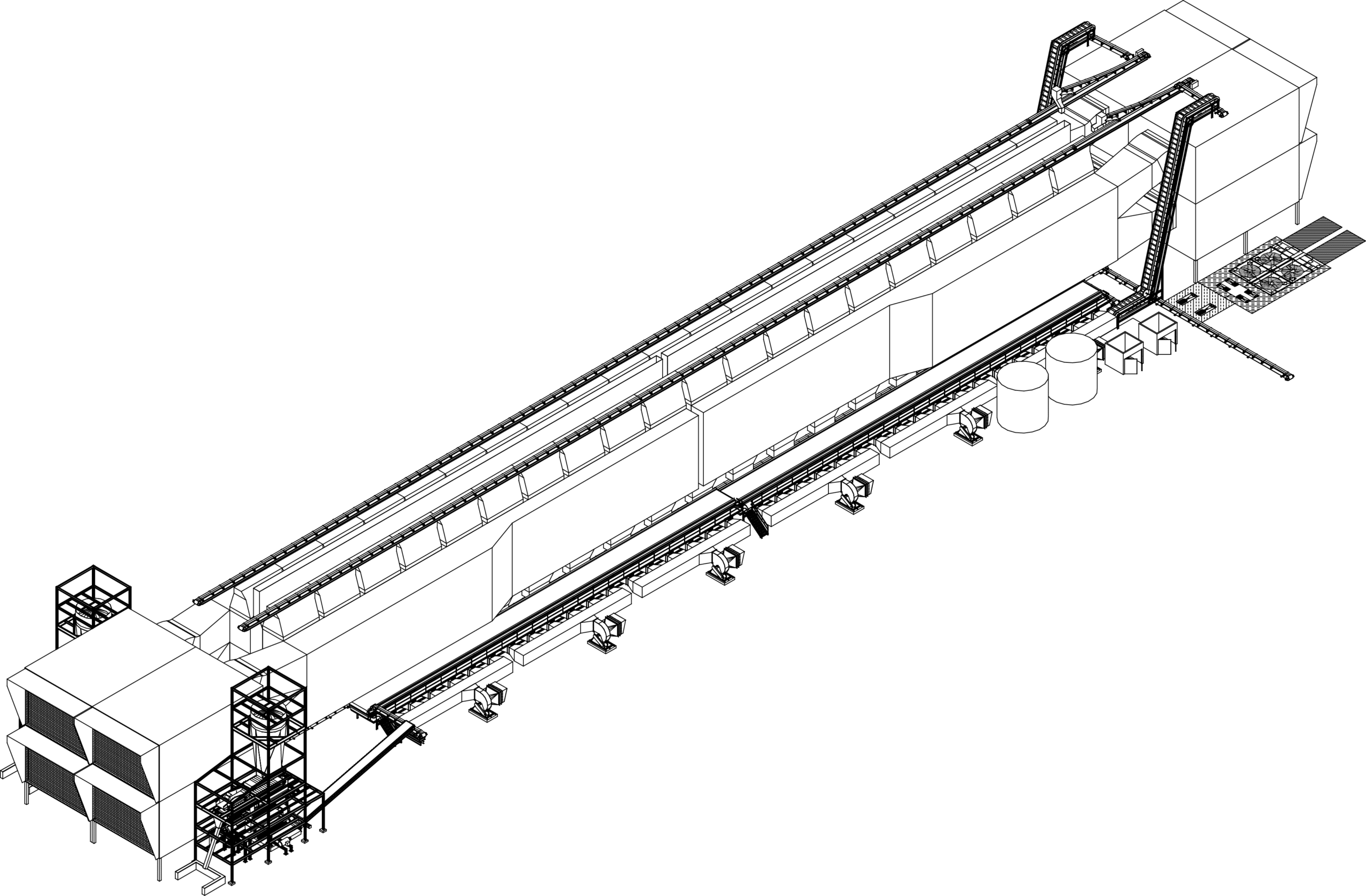

Commercial Scale Design

The Coldry Pilot Plant has informed the design of the commercial-scale Coldry modules that will underpin commercial plants.

These modules have been designed to produce:

- 340,000 TPA of Coldry from 60% moisture coals,

- 440,000 TPA of Coldry from 50% moisture coals, or

- 600,000 TPA of Coldry from 40% moisture coals.

The COLDry Product

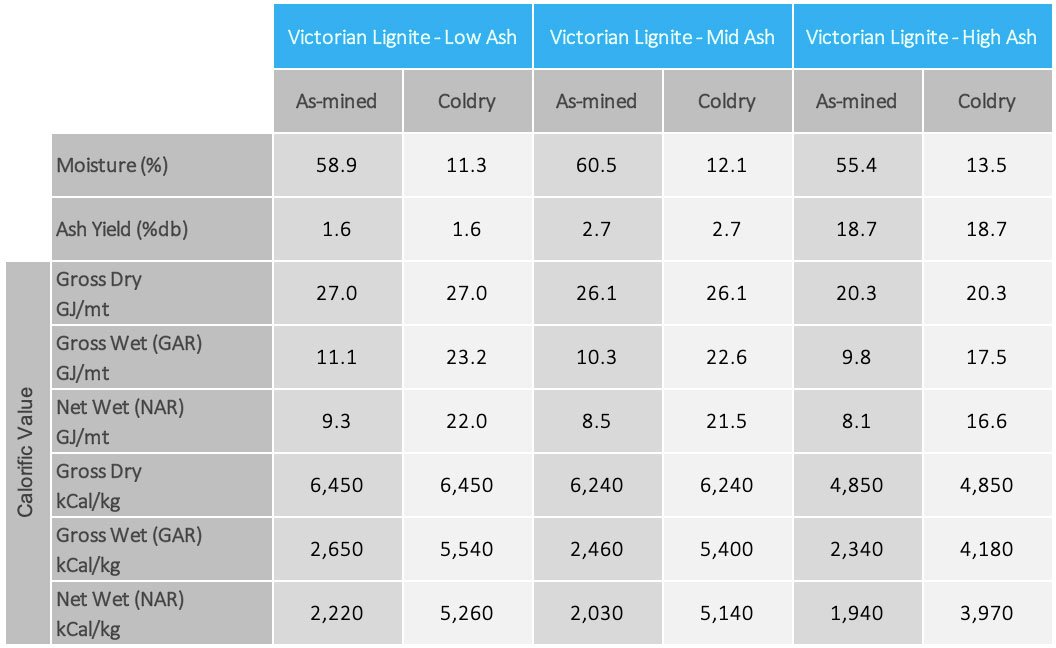

COLDry is a solid fuel with a net energy value similar in range to that of many black coals.

Key Features

- Exponentially enhanced net energy content increased up to 285% for 60% moisture Victorian Latrobe Valley lignite

- The spontaneous combustion risk of typical lignite is greatly reduced to that of normal black coals, making it safe to transport

- Ideal feedstock for high-value low and zero-emission applications such as clean hydrogen production, iron and steel making (via HydrMOR process), agricultural char and associated derivatives

Stable

Testing by the University of Queensland places COLDry in the same ‘spontaneous combustion’ risk range as thermal (black) coals currently exported from Queensland and NSW. The COLDry process changes the physical structure to the point it no longer has the same ‘high-risk’ of spontaneously combusting as raw lignite.

Valuable

As a resource for clean hydrogen production, COLDry enables the net-zero emission delivery of a scalable, affordable solution.

Versatile

The product is versatile and can serve as a valuable feedstock for a range of applications.

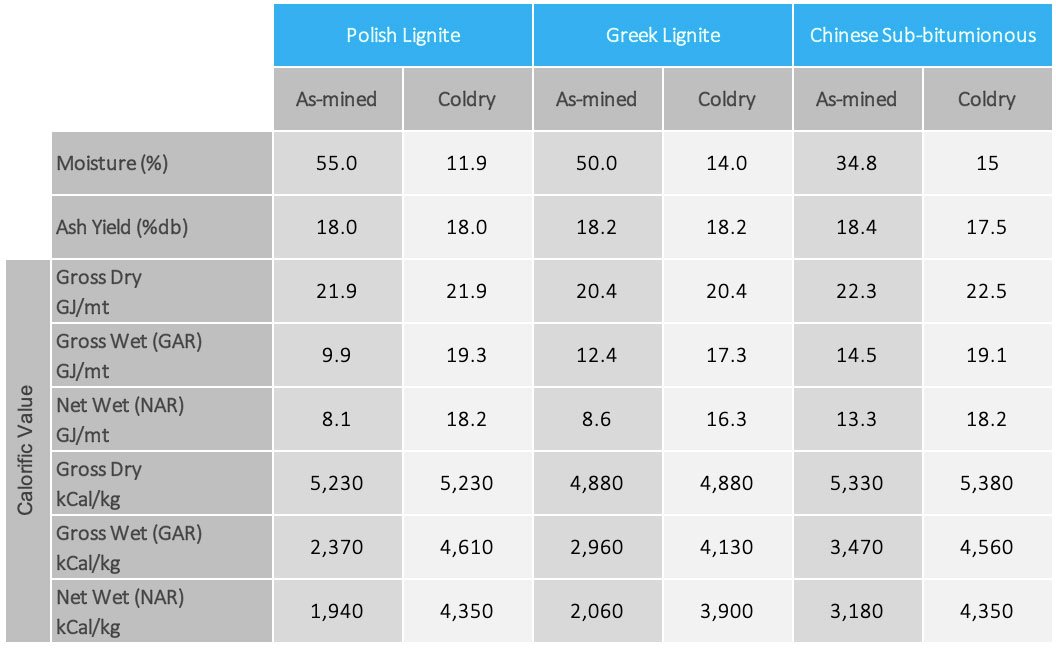

Product Test Results

The following indicative results show the analysis before and after processing.

Intellectual Property Strategy

Our core asset is our Intellectual Property and as such must inform and leverage our Business Strategy.

Key aspects of IP protection include:

- Patents – The COLDry Process is covered by patents in all major markets with significant lignite deposits and a mature legal framework

- Confidentiality Agreements – Engagement with potential partners and customers is covered by comprehensive agreements

- Licence Agreements – Technology Transfer is protected by detailed agreements to minimise risk and maximise compliance

Patents – COLDry

| Country | Patent No / Patent Application No | Status |

| Australia | 2004274520 | Granted |

| Canada | 2540285 | Granted |

| China (incl. Hong Kong) | ZL200480031850.2 | Granted |

| European Patent Office | 1680637 | Granted |

| India | 265936 | Granted |

| New Zealand | 546098 | Granted |

| USA | 7992319 | Granted |

Note: The Company had originally applied for coverage in Brazil, but has elected to abandon that coverage due to the incompatible quality of the lignite (extremely high inorganic contamination levels).