Technology

Detail

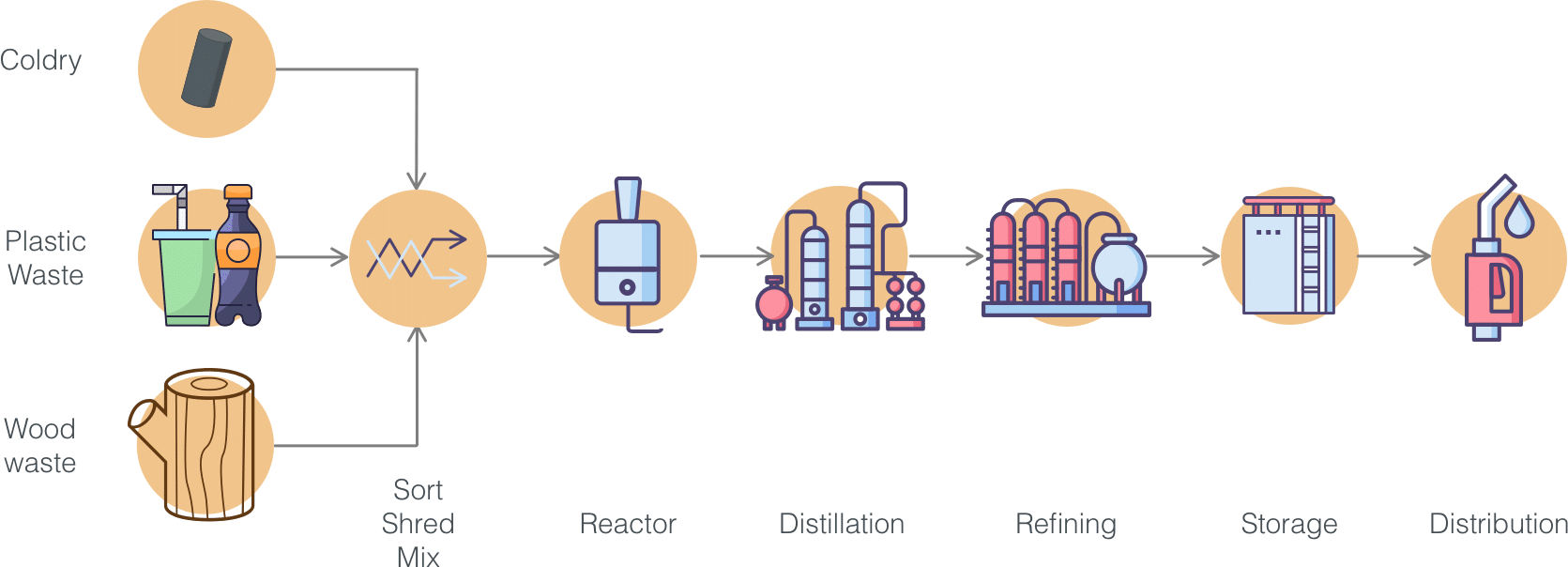

The Process

Catalytic depolymerisation has the ability to efficiently convert a variety of feedstocks, such as construction and industrial waste, plastics or coal, into high-quality renewable diesel which can be used in both the transport sector or for energy generation.

Catalytic depolymerisation is particularly relevant to addressing Australia’s growing waste and recycling burden, representing a net economically beneficial solution for local governments, public authorities, energy providers and remote communities. Catalytic depolymerisation will help a broad range of organisations realise improved economic value, environmental outcomes, energy security and social value.

This renewable diesel can be used in transportation and vehicle fleets as well as to generate power when coupled with diesel-powered generating plants. Research and development efforts have focused on delivering production levels that provide commercially viable and competitive returns to investors, providing a point of differentiation in the WTE market.

Accordingly, the CDP technology has progressed significantly towards being able to offer a Process Guarantee that ensures continuous and appropriate commercial production levels and diesel quality for the type of feedstock.

The product

The output from the CDP-WTE plant is a liquid hydrocarbon.

Other components include bitumen and asphalt.

Standard refining processes are applied to produce automotive diesel.

Four Main Benefits of CDP-WTE technology

1. Wide variety of waste

With further testing, it is expected that the technology will be able to process a mix of waste feedstock, including:

- Biomass such as paper, cellulose, fats, wood and organic squeezing residues; and

- Fossil fuel derived materials e.g. coal, plastics, oils, bitumen

Eventually, the waste streams could include:

- Municipal Solid Waste (MSW), Construction and Demolition (C&D) waste

- All kinds of plastics and synthetics (PP, PET etc.)

- Biomass (waste plant material), wood, bioderived residues like leaves, straw

- Animal waste

- Coal, crude oil, bitumen, old tyres and refinery residues

- Waste oil, fat and biosolids

2. Environmentally sound management of waste

In comparison to other waste to fuel processes the CDP process is a reaction process that occurs at relatively low temperature and low pressure, complementing the low temperature, low-pressure approach of the Coldry process:

- Low temperature and low-pressure conditions are a proxy for lower opex and capex and avoid the production of toxic substances such as dioxin;

- The process does not consume any water, reducing the impact on the environment and community, unlike other technologies such as gasification and supercritical processes, and;

- A lower carbon footprint due to a relatively low reaction temperature (~ 280°C) unlike other upgrading technologies such as pyrolysis (>500°C) and gasification (>700°C).

3. Diesel offtake

The high-quality diesel produced through the CDP process not only meets AS3570, but can provide the following benefits: •not strongly acidic like pyrolysis oils; •reduced costs per litre; •diesel can be used to power generators for remote communities; and, •reduced emissions.

Diesel offtake volumes could be met through a combination of fuel supply agreements to local independent fuel retailers and bulk supply agents and direct supply to the waste management company and logistics transport fleets.

4. Scalable technology

Local governments and other regional waste management operations are required to manage waste environmentally, socially and economically for their customers.

The CDP process is scalable and could be based on the CDP1500 module size, a 1,500 litre per hour renewable diesel unit. A project comprised of three CDP1500 plants could deliver an aggregate of 4500L of diesel per hour from 115,000 tonnes of waste per annum.

Commercialisation Pathway

ECT’s commercialisation strategy is a core part of its business model. Revenue is the goal.

- Commercialisation is the process that converts ideas, research, or prototypes into viable products and production systems.

- Commercialisation relies on the creation of effective manufacturing, supply chain and implementation strategies.

- Research, development and commercialisation require significant investment before revenue is realised.

- Our commercialisation strategy also includes marketing and sales systems, which will seek to drive the transition from research investment to revenue generation.

The CDP WTE technology presents significant potential synergies with the Company’s lignite drying process; Coldry, including:

- The CDP WTE process performance, efficiency and yield can benefit from the blending of Coldry with waste to provide improved feedstock consistency and process reaction conditions

- The Coldry process can benefit technically and financially via the harvesting of free waste heat from the CDP process, while enabling bankability of the overall project via exposure to the higher value liquid fuel market, compared to the international coal market.

The integration of CDP-WTE with Coldry may elicit a deeper and broader acceptance or ‘social license’ for the future use of brown coal in Australia.

In line with these substantial opportunities, we will be pursuing the development of a vertically integrated, Coldry-enabled, CDP-WTE solution for the production of diesel fuel as a part of our proposed Latrobe Valley project.

Latrobe Valley Project

This project is a key initiative focused on the development of a 170,000 tpa – 300,000 tpa Coldry module in Victoria’s Latrobe Valley, targeted at supplying solid fuel to the utility steam and hot water market and producing diesel via the CDP-WTE process.

The addition of the CDP technology to the Latrobe Valley Coldry Project (LVCP) is intended to provide significant potential margins to Coldry solid fuel pellets via the conversion to higher-value products, including diesel, bitumen and asphalt.

Waste-to-energy projects all suffer from a common challenge – access to long-term and continuous waste feedstock supplies. Coupling Coldry with CDP will help to respond to this challenge as Coldry will serve as a baseload chemical feedstock, assuring continuous production and allowing alternative waste feedstocks to be sourced as and when they are feasibly accessible. This will also demonstrate to the broader community and the government how Victoria’s world-class lignite reserves can be harnessed by innovative processes as a more valuable chemical feedstock instead of it simply being burned as a direct thermal energy source to make electricity.