Investor News

Brown coal the hydrogen economy stepping stone

The battleground has been defined: Green vs. Brown hydrogen.

The Australian's Ben Packham covers the topic in his recent article below.

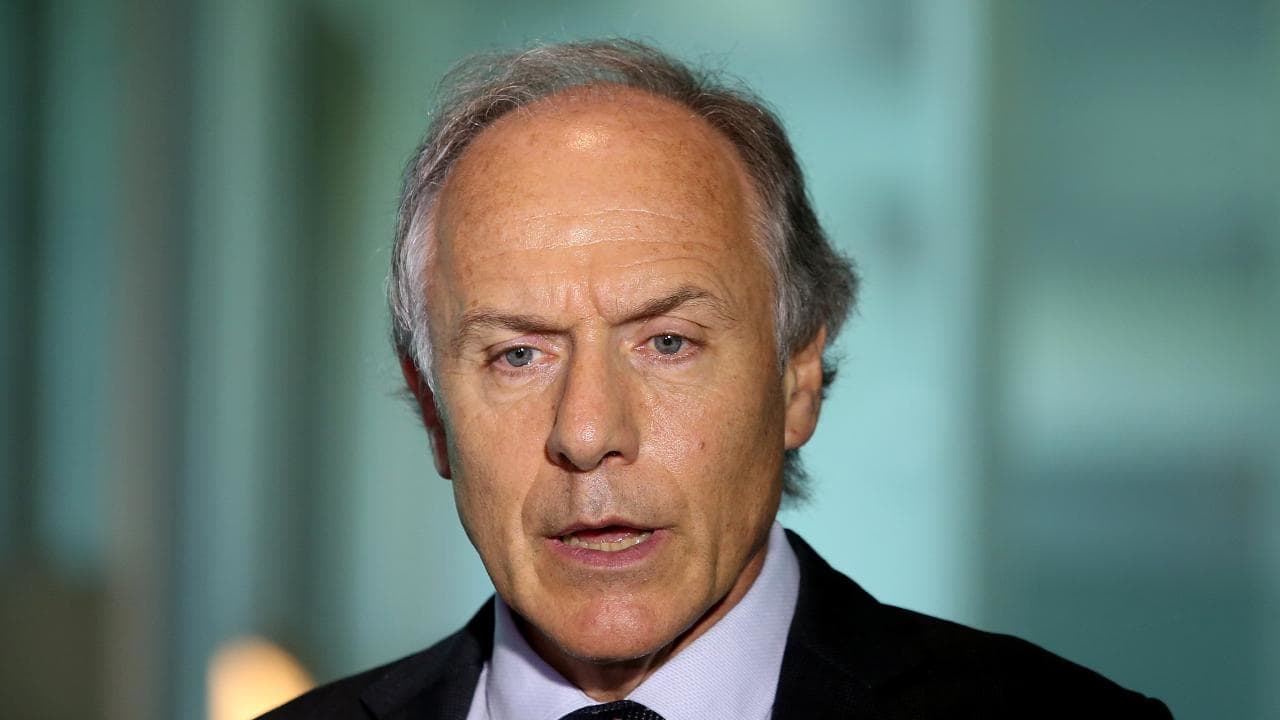

Our Chief Scientist, Alan Finkel, has endorsed 'green' hydrogen while acknowledging the need to rely on 'brown' hydrogen as a stepping stone.

Late last week, the Federal and State government announced their $100 million support for a $500 million 4-year project led by Japanese industrial giant Kawasaki Heavy Industries (KHI) to prove up coal-to-hydrogen in Victoria's Latrobe Valley.

This project comes under the banner of 'brown' hydrogen.

The project, which focuses largely on proving the hydrogen supply chain, aims to produce low-emissions hydrogen from traditional industrial processes and CCS (carbon capture and storage).

The prize? A slice of the hydrogen 'boom' is estimated to be worth $1.8 trillion annually by 2050.

You'll be reading a lot more about hydrogen. It's seen as the 'clean' transport fuel of the future, with no CO2 emissions.

We previously announced our own research into hydrogen production from brown coal, a process we call COHgen, short for Catalytic Organic Hydrogen generation. It's still lab-scale, and we're in the process of patenting the invention, but suffice it to say, we think it may be a lower-emission, lower-cost method for hydrogen production from brown coal.

We have four years to develop COHgen to the point where the likes of KHI can evaluate it as an option for future commercial deployment.

But returning to the article, which quotes Finkel as saying 'brown' hydrogen is a stepping stone to 'green' hydrogen. This is an unusual admission from our Chief Scientist, who is known for recommending a high renewable energy target of 42% by 2030, despite the affordability and reliability issues currently impacting consumers.

The concept of 'green' hydrogen is simple enough:

- Wind and solar power create electricity

- Electricity is used to 'split' water into H2 and O via a process called electrolysis

- The H2 is separated and stored for later use in hydrogen fuel cells

Currently, electrolysis accounts for 4% of hydrogen production because it's expensive.

It takes more energy to split hydrogen from oxygen using electricity than you get when you subsequently use that hydrogen to power a car.

The natural gas route accounts for 48% of the hydrogen produced annually. It involves a process called steam reforming. Wikipedia has the technical details for those interested. The key point here is the process operates between 700 and 1100 degrees Celsius and generates CO2.

Gas is expensive here in Australia, but we have plenty of coal. Brown coal, because of its chemical differences, can yield more hydrogen than black coal.

Our brown coal is cheaper to mine than black coal, making it the ideal low-cost candidate for coal-to-hydrogen.

Unlike the natural gas route, coal needs to be gasified first.

Gasification produces a mixture of carbon monoxide, hydrogen, carbon dioxide, methane and water vapour.

Our COHgen process is relatively low-temperature, lower in CO2 emissions than the traditional gasification or steam reforming route, and delivers a higher H2 yield. We think it will attract future attention.

With this in mind, let's perform a reality check on the 'green' hydrogen model.

It's a marketer's dream...

Australia could soon be “exporting sunshine” in the form of renewable energy-produced hydrogen, creating an industry that could rival Australia’s LNG exports within decades.

Exporting sunshine and wind power sounds wonderful.

Green hydrogen promises to take our excess Wind and Solar power and 'store' it as hydrogen. However, given our tight electricity market, the intermittent nature of Wind, and the increasing need for both Wind and Solar to charge batteries or pump hydro to stabilise energy supply, there may not be a lot of 'excess'. Certainly not enough to capitalise on that $1.8 trillion hydrogen market. We'd need dedicated Wind and Solar assets to meet hydrogen orders.

The challenge is scale. Add Finkel knows it.

It's all well and good to talk about exporting sunshine to Japan to power their cars, but what does a quick back-of-the-envelope calculation reveal about the scale challenge?

Let's start with Australia. What would a 'green' hydrogen-powered passenger car fleet look like today?

The ABS tells us we have ~13.7 million passenger vehicles travelling a total of ~179.6 billion kilometres a year. If they were all hydrogen-powered, we would need an additional ~15,800 3MW wind turbines with a nameplate capacity of 47,400 MW to deliver the ~124.9 billion kWh needed to split water to make hydrogen. This assumes an average Wind capacity factor of 30%.

For context, Australia has ~4,462MW of Wind capacity today, delivering an average of ~1,338MW (30% capacity factor).

What about solar? Bottled sunshine sounds great!

Solar PV, the type you see on rooftops, would need an additional ~71,000 MW of installed capacity dedicated to hydrogen production just to fuel Australia's passenger car fleet. We currently have ~7,000 MW of capacity, mostly directed at keeping the lights on.

Large-scale Solar makes more sense than relying on small-scale solar PV. Even so, we'd need ~31,000 MW of new large-scale solar plant. The existing capacity is 323MW.

Jump to Japan, with its fleet of 61 million passenger vehicles travelling 292.8 billion km per year. We'd need ~25,800 3MW Wind turbines to deliver the ~77,400MW additional capacity needed to meet Japan's needs. Or an additional ~51,600 MW of large-scale solar.

Not to say it can't be done. It's been done before for oil and gas infrastructure.

We just need to understand that the warm and fuzzy concept of exporting sunshine (or wind) makes it sound easy. In reality, taking advantage of the $1.8 trillion opportunity requires a lot of work and investment over several generations.

Returning to the article, there's an incredibly important point:

The group acknowledges the “green hydrogen story is more saleable than brown hydrogen” but says brown hydrogen is closer to being commercialised.

We agree.

Related links:

- Energy debate heats up in a tale of two priorities (Sydney Morning Herald)

- Converting coal to hydrogen

Read more...

Chief Scientist Alan Finkel talks up green hydrogen exports

13 April 2018 | The Australian | Ben Packham

Chief Scientist Alan Finkel’s hydrogen power strategy group says Australia could soon be “exporting sunshine” in the form of renewable energy-produced hydrogen, creating an industry that could rival Australia’s LNG exports within decades.

Source ($): Finkel talks up green hydrogen